[svp]http://www.youtube.com/watch?v=teBGz3LK3E4[/svp]

In this video, we will discuss the most common reasons a p0013 and P0014 code may be set in your car or truck.

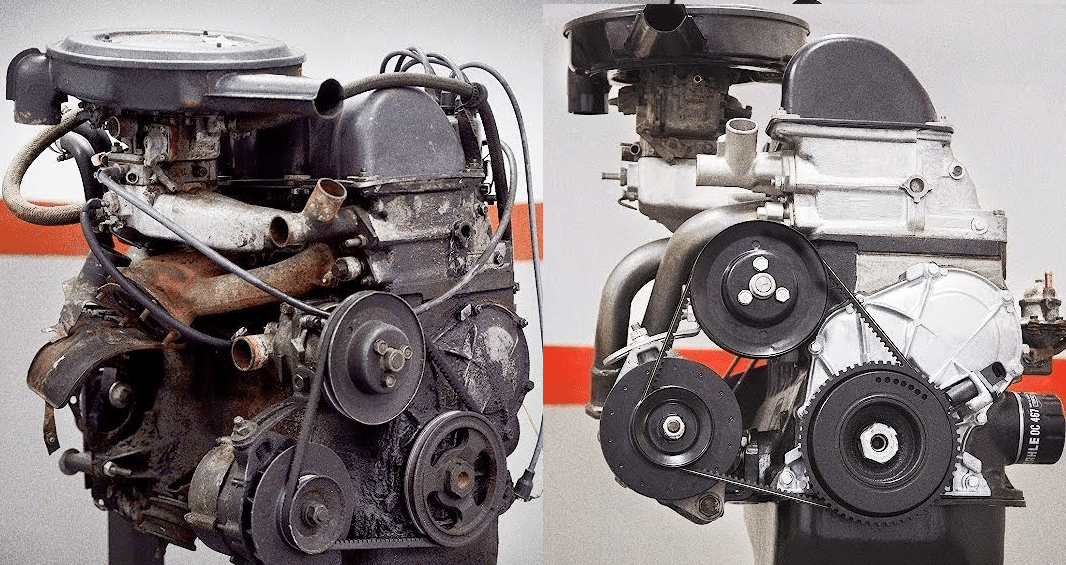

So we got a p0013 exhaust camshaft position actuator valve solenoid circuit and a p0014 exhaust camshaft position performance. The most common reason this code will set and cause your check engine light to come on is due to low engine oil. Or oil is not being changed when it should.

So if your engine oil looks low or dirty that is definitely the first thing you will want to do to try and fix both code P0013 and code P0014.

The next thing you will want to do is remove both VVT solenoids and test them by supplying power and ground, if it clicks the VVT valve is good.

Before reinstalling both VVT solenoids I would recommend cleaning them with brake clean. In most cases just cleaning VVT solenoids and changing engine oil will be enuff to fix P0013 and P0014.

Let us know in the comments if this worked for you!

The Most Common Cost of repair is $250 to $450

The Most Common labor 1 hr

You can get these variable valve timing solenoids on amazon here: https://amzn.to/3smB7Cm

When it comes to maintaining your vehicle, there are a few common issues that can arise. One of these issues is related to the Variable Valve Timing (VVT) Solenoid. The P0013 and P0014 codes are related to this issue and can be caused by a variety of factors. In this article, we will explore the common causes of these codes and the “cheapest fix” for resolving them.

What is the VVT Solenoid?

The VVT solenoid is a small valve that controls the amount of oil flow to the camshaft. This allows the camshaft to adjust the timing of the valves, which improves engine efficiency and performance. The VVT solenoid is controlled by the engine control module (ECM) and is triggered by a signal from the camshaft position sensor.

Common Causes of P0013 and P0014 Codes

There are a few common causes of P0013 and P0014 codes. These include:

- A malfunctioning VVT solenoid

- A clogged oil passage

- An oil leak

- A faulty camshaft position sensor

- A malfunctioning engine control module

The “Cheapest Fix” for Resolving P0013 and P0014 Codes

The “cheapest fix” for resolving P0013 and P0014 codes is to simply replace the VVT solenoid. This is a relatively inexpensive repair and can often be done without having to remove the engine. However, it is important to also check for other issues that may be causing the problem, such as a clogged oil passage or an oil leak.

How to Prevent P0013 and P0014 Codes

To prevent P0013 and P0014 codes, it is important to regularly maintain your vehicle and change the oil as recommended by the manufacturer. This will help to keep the oil passages clean and free of debris. Additionally, it is important to address any oil leaks as soon as they are discovered to prevent further damage to the VVT solenoid.

In conclusion, P0013 and P0014 codes are common issues that can be caused by a variety of factors. The “cheapest fix” for resolving these codes is to simply replace the VVT solenoid. However, it is important to also check for other issues that may be causing the problem and address them as well. By regularly maintaining your vehicle and addressing any issues as soon as they are discovered, you can help to prevent P0013 and P0014 codes from occurring in the first place.

Q&A

Q1. What is the VVT Solenoid and how does it work?

A1. The VVT Solenoid is a small valve that controls the amount of oil flow to the camshaft. This allows the camshaft to adjust the timing of the valves, which improves engine efficiency and performance. The VVT solenoid is controlled by the engine control module (ECM) and is triggered by a signal from the camshaft position sensor.

Q2. What are the common causes of P0013 and P0014 codes?

A2. The common causes of P0013 and P0014 codes include: a malfunctioning VVT solenoid, a clogged oil passage, an oil leak, a faulty camshaft position sensor, and a malfunctioning engine control module.

Q3. What is the cheapest fix for resolving P0013 and P0014 codes?

A3. The cheapest fix for resolving P0013 and P0014 codes is to simply replace the VVT solenoid. This is a relatively inexpensive repair and can often be done without having to remove the engine.

Q4. How can I prevent P0013 and P0014 codes from happening?

A4. To prevent P0013 and P0014 codes, it is important to regularly maintain your vehicle and change the oil as recommended by the manufacturer. This will help to keep the oil passages clean and free of debris. Additionally, it is important to address any oil leaks as soon as they are discovered to prevent further damage to the VVT solenoid.

Q5. Is it important to check for other issues when resolving P0013 and P0014 codes?

A5. Yes, it is important to also check for other issues that may be causing the problem, such as a clogged oil passage or an oil leak when resolving P0013 and P0014 codes. This will ensure that the underlying cause of the problem is addressed and will prevent the codes from recurring.

Q6. How much does it cost to repair codes p0013 and p0014 codes?

A6. The cost of repairing codes P0013 and P0014 can vary depending on the make and model of your vehicle, as well as the specific issues that are causing the codes to appear. In general, the cost can range from a few hundred dollars for a simple fix, such as replacing a faulty camshaft sensor, to several thousand dollars for a more complex repair, such as replacing the camshaft position actuator or the timing chain. It is best to consult with a mechanic or dealership to get a more accurate estimate for your specific vehicle.

Subscribe to my youtube channel here: https://goo.gl/j1pCfn

For the most common automotive fixes to the most common car and truck problems. DIY auto repair to help you save money.

Connect with me:

Facebook: https://www.facebook.com/groups/diyrepair

Check out The Flat Rate Mechanics Tool Store on Amazon https://goo.gl/M8MpdC

The Flat Rate Mechanic. 27-year ASE Master Automotive Technician and Advanced level ASE certified here to help you save money on your automotive repairs